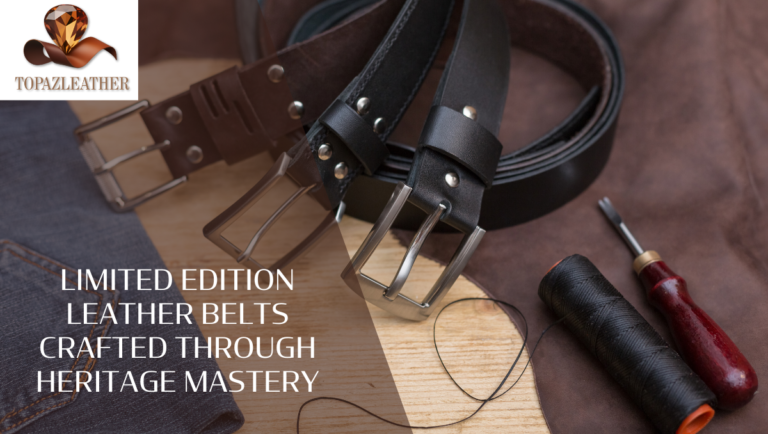

From Hide to Heirloom: The Belt-Making Process Explained

Crafting a leather belt is more than assembling materials—it’s an art form. Understanding the belt-making process helps appreciate the skill, precision, and time invested in creating a durable, stylish accessory. Whether you’re a leather enthusiast, an aspiring artisan, or a consumer seeking quality, this guide explains each step of belt-making, from raw hide to heirloom-ready craftsmanship.

Step 1: Selecting the Right Leather

The journey begins with choosing high-quality leather.

- Full-grain leather: Most durable, develops a natural patina over time.

- Top-grain leather: Smooth finish, slightly less rugged but elegant.

- Vegetable-tanned leather: Eco-friendly option, perfect for natural dyeing.

Selecting the proper hide determines the belt’s longevity, flexibility, and appearance.

Pro Tip: Check for uniform texture, minimal blemishes, and proper thickness for belt durability.

Step 2: Cutting the Leather

Cutting transforms raw hides into precise belt strips.

- Artisans use sharp knives or specialised cutting tools.

- Strips are measured to standard widths (1.25”–1.5” typical).

- Edges may be bevelled for a refined finish.

Accuracy in cutting ensures consistent size and style for every belt.

Step 3: Conditioning and Dyeing

Leather requires preparation before assembly:

- Conditioning: Oils and waxes soften the leather and prevent cracking.

- Dyeing: Hand-applied or drum-dyed to achieve rich, even colour.

- Drying: Slow air-drying maintains integrity and prevents shrinkage.

Proper conditioning extends the belt’s lifespan and enhances its visual appeal.

Step 4: Edge Finishing

Edge finishing gives a belt its polished, professional look.

- Edges are sanded smooth.

- Burnishing adds shine and seals fibres.

- Edge paint may be applied for extra durability.

Well-finished edges prevent fraying and elevate overall aesthetics.

Step 5: Stitching and Assembly

Stitching is both functional and decorative:

- Hand-stitching is precise, strong, and shows craftsmanship.

- Machines can speed up production but may reduce artisanal appeal.

- Buckle attachment is reinforced for strength.

Stitching ensures the belt withstands daily wear while maintaining elegance.

Step 6: Buckle Selection and Installation

The buckle completes the belt’s functionality and style.

- Materials include stainless steel, brass, or nickel.

- Styles vary: classic prong, ratchet, or reversible designs.

- Secure attachment with rivets or stitching ensures longevity.

Choosing the right buckle complements the leather and the belt’s overall design.

Step 7: Quality Control and Finishing Touches

Every belt undergoes thorough inspection:

- Check stitching consistency and edge quality.

- Inspect dye uniformity and leather surface.

- Test buckle functionality and belt flexibility.

Attention to detail ensures the belt meets heirloom standards and customer satisfaction.

The Role of Artisanship

Handmade belts reflect the skill and passion of artisans:

- Unique patterns, hand-burnished edges, and custom dyeing.

- Each piece tells a story, unlike mass-produced alternatives.

- Supporting artisans preserves traditional craftsmanship.

According to Forbes, demand for handcrafted leather goods has increased by 25% over the past five years, driven by growing consumer appreciation for quality and sustainability.

Sustainability and Ethical Practices

Modern belt making increasingly emphasises ethical sourcing:

- Leather sourced from responsible tanneries reduces environmental impact.

- Vegetable-tanning and minimal chemical use promote eco-friendliness.

- Supporting artisans helps sustain local communities and fair labour practices.

Sustainable production aligns with consumer expectations for premium, ethical products.

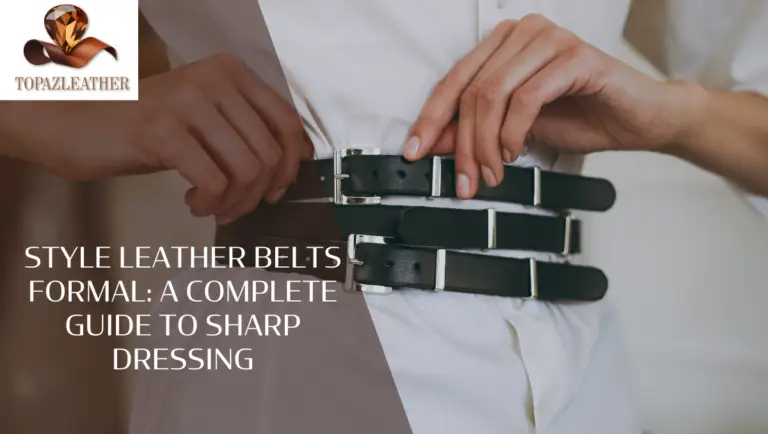

Common Belt Styles and Uses

Understanding style helps in selecting the right belt:

|

Style |

Features |

Ideal Use |

|

Casual |

Soft leather, simple buckle |

Jeans, daily wear |

|

Formal |

Stiff, polished leather |

Office, suits, formal events |

|

Dress |

Slim, sleek |

Elegant attire |

|

Reversible |

Two-coloured option |

Versatile wardrobe |

Each style reflects purpose, material, and craftsmanship.

Tips for Caring for Handmade Belts

Proper care extends lifespan:

- Store flat or rolled in a cool, dry place.

- Condition leather periodically with wax or oil.

- Avoid exposure to water and extreme heat.

- Rotate belts to reduce wear.

Well-maintained belts can become family heirlooms, lasting decades.

Why Handcrafted Belts Outperform Mass-Market Belts

Mass-produced belts may be cheaper but lack:

- Longevity and durability

- Artisan-quality stitching

- Unique character

- Ethical sourcing

Investing in handmade belts ensures lasting style, utility, and sustainable choice.

Conclusion

The belt-making process combines artistry, precision, and sustainability. From hide selection to final buckle installation, each step defines the belt’s quality, durability, and elegance.

Choosing handcrafted leather belts:

- Supports skilled artisans

- Provides heirloom-quality accessories

- Promotes sustainable and ethical practices

FAQs

The belt-making process includes selecting quality leather, cutting, dyeing, edge finishing, stitching, buckle installation, and quality control to create durable, stylish belts.

Full-grain, top-grain, and vegetable-tanned leathers are commonly used for durability, aesthetics, and eco-friendliness.

Depending on complexity, handcrafted belts can take several hours to multiple days to complete, including dyeing and finishing.

Handmade belts offer superior quality, durability, unique designs, and ethical sourcing compared to factory-made alternatives.

Yes, artisans often provide embossing, custom colours, or patterns to create unique, personal gifts.