The Importance of Leather Quality Control

At Topaz Leather, leather quality control defines the standard of excellence in every wallet, belt, and bag. Luxury buyers in the UK demand both visual perfection and enduring functionality, and only meticulous inspection can ensure this. Each hide undergoes rigorous evaluation to verify texture, suppleness, and structural integrity. Understanding leather quality control provides insight into how Topaz Leather maintains its reputation for premium craftsmanship and ethical production.

Our process begins with selecting hides that meet stringent specifications. Full-grain and top-grain leathers arrive from certified tanneries that adhere to the Leather Working Group standards. These hides possess the natural oils, tensile strength, and surface characteristics required for longevity and luxury appeal.

Initial Inspection and Material Selection

The first stage of leather quality control evaluates natural markings, grain consistency, and overall softness. Each hide undergoes tactile and visual assessment to ensure uniformity and durability. Topaz Leather sources materials exclusively from suppliers with a proven commitment to ethical practices and environmental sustainability, aligning with guidance from the Sustainable Apparel Coalition.

Hides that meet these standards enter the production line, while any leather with imperfections or inconsistencies is set aside. This rigorous selection ensures that every handcrafted piece embodies uncompromising quality, a principle highlighted by the British Fashion Council as critical in maintaining luxury credibility.

Precision Craftsmanship Verification

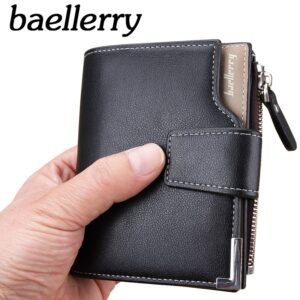

Once selected, leather undergoes detailed evaluation throughout the artisanal process. Leather quality control extends to cutting, stitching, and edge finishing. Every cut must preserve grain integrity, while stitching is monitored to guarantee tensile strength and symmetry. Topaz Leather artisans employ handcrafted techniques recognised by the Crafts Council UK, blending heritage skills with contemporary standards.

Edge burnishing, folding, and dye application receive careful attention to maintain aesthetic consistency and structural resilience. Each step follows documented inspection protocols, ensuring that defects are addressed before assembly is completed. This vigilance guarantees that UK buyers experience products that combine style with longevity.

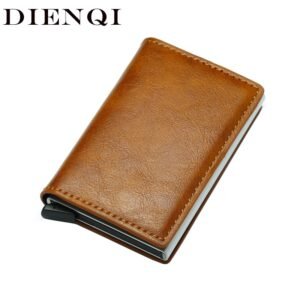

Colour, Finish, and Surface Assurance

The application of dyes and finishes represents a crucial stage in leather quality control. Topaz Leather applies vegetable-tanned and eco-friendly finishes to enhance visual appeal while preserving natural characteristics. Colour uniformity, sheen, and surface smoothness undergo multiple inspections to meet luxury expectations.

Research by the Society of Leather Technologists and Chemists underscores the importance of colourfastness and finish integrity in prolonging leather lifespan. By adhering to these standards, Topaz Leather ensures that every accessory retains vibrancy and elegance for years of use.

Functional Testing and Structural Verification

Leather quality control encompasses functional testing. Bags, wallets, and belts are assessed under stress conditions simulating daily wear. Closure mechanisms, strap strength, and interior compartments are evaluated to verify usability without compromising the design. Topaz Leather integrates these tests to give UK customers confidence that their purchase will withstand both style demands and practical use.

The British Standards Institution recognises that structured quality assessment enhances both product reliability and consumer trust, a principle central to Topaz Leather’s brand ethos.

Ethical Standards and Sustainability

Sustainability forms a core component of leather quality control. Topaz Leather ensures that every hide meets ethical sourcing and environmental compliance criteria. From tannery certification to eco-conscious finishing techniques, each stage reduces ecological impact while maintaining premium standards.

The Leather UK authority supports transparent, traceable supply chains, ensuring that UK luxury buyers receive products that reflect both heritage craftsmanship and responsible production.

Packaging and Final Review

Before dispatch, every Topaz Leather item undergoes final leather quality control verification. Artisans inspect stitching, surface integrity, colour consistency, and functional elements. Packaging employs protective, sustainable materials to ensure products arrive in pristine condition, emphasising the premium experience.

The Which? consumer guidance reiterates that attention to detail in packaging and final inspection reinforces buyer confidence, particularly in luxury markets where tactile and visual excellence determine satisfaction.

Continuous Improvement and Feedback Integration

Topaz Leather continually refines its leather quality control. Feedback from UK clients, combined with industry benchmarking, informs training, process adjustments, and material sourcing. This cycle enhances product consistency, durability, and aesthetic excellence, reinforcing the brand’s authority in luxury handmade leather.

Monitoring market trends and technological advancements in leather processing allows Topaz Leather to balance traditional craftsmanship with modern standards, maintaining its relevance and leadership in the UK luxury sector.

Experience Unmatched Craftsmanship

Topaz Leather exemplifies leather quality control by blending heritage techniques, ethical sourcing, and meticulous inspection. Each wallet, belt, and bag reflects a commitment to excellence, offering UK buyers products that endure in both style and substance.

+447477227847

Hello@topazleather.com

www.topazleather.com

FAQs

It involves inspecting hides, verifying stitching, testing finishes, and assessing functionality to ensure premium performance.

Rigorous checks at each production stage and high-quality full-grain hides guarantee long-lasting products.

Yes, all hides meet ethical, certified, and sustainable sourcing standards.

Every item undergoes multiple inspections, including final quality verification before dispatch.

Yes, production and quality control adhere to British Standards Institution guidance and luxury industry benchmarks.